- Japanese

- English

- Home

- » Technology & Development

In-wheel motor

This is technology for inserting motors inside the vehicle wheels.

The technology has been made feasible by developing a compact, high-efficiency motor.

The main advantages are the high energy efficiency, large usable space in the vehicle body, and highly simple vehicle structure.

While there have been concerns that this design, with the large weight under the suspension springs, would result in poorer riding comfort, demonstration tests have shown this not to be the case.

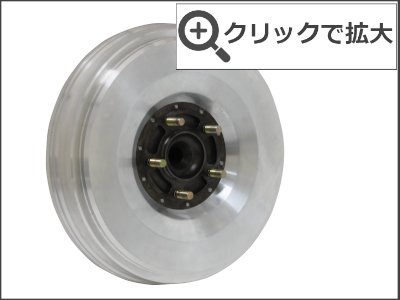

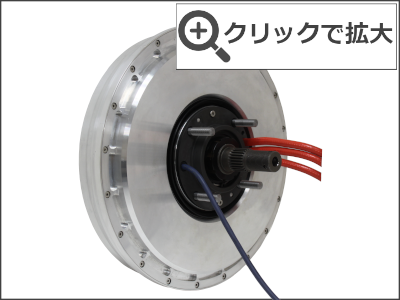

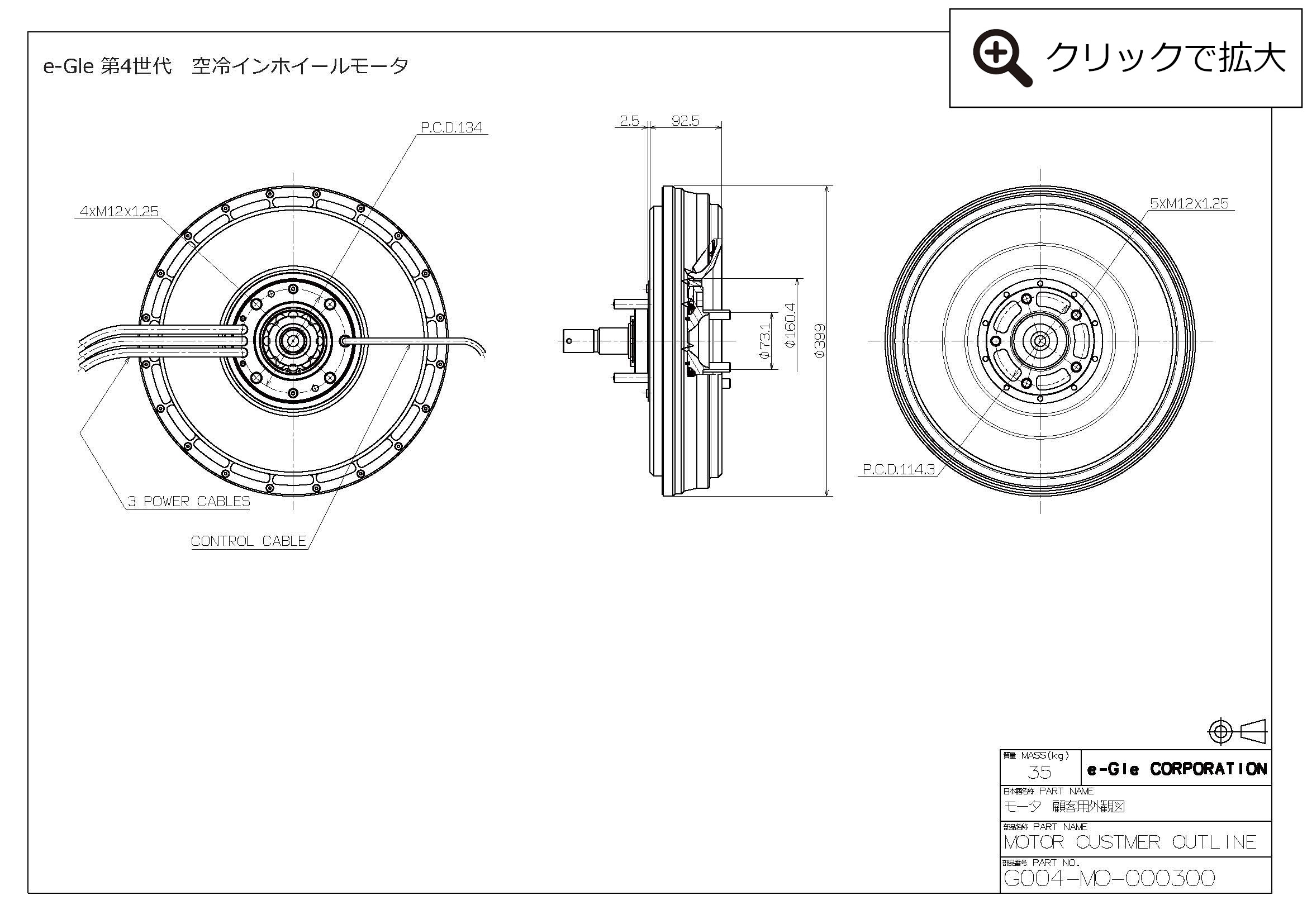

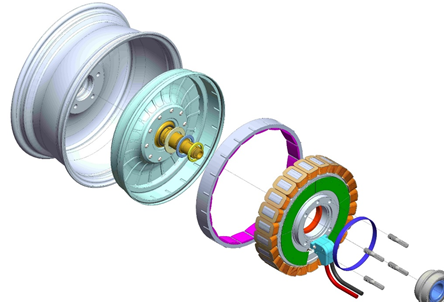

e-Gle's 4th-Generation Air-cooled In-wheel Drive

Motor type: Outer rotor direct-drive in-wheel motorCooling method: Air cooling

Dimensions: 399 mm x 92.5 mm

Weight: 35kg

Max torque: 620Nm

Maximum output: 65kw

Acquire GB/T18488 Certification for Chinese Motor Standard

|

|

|

e-Gle's 5th-Generation In-wheel Drive

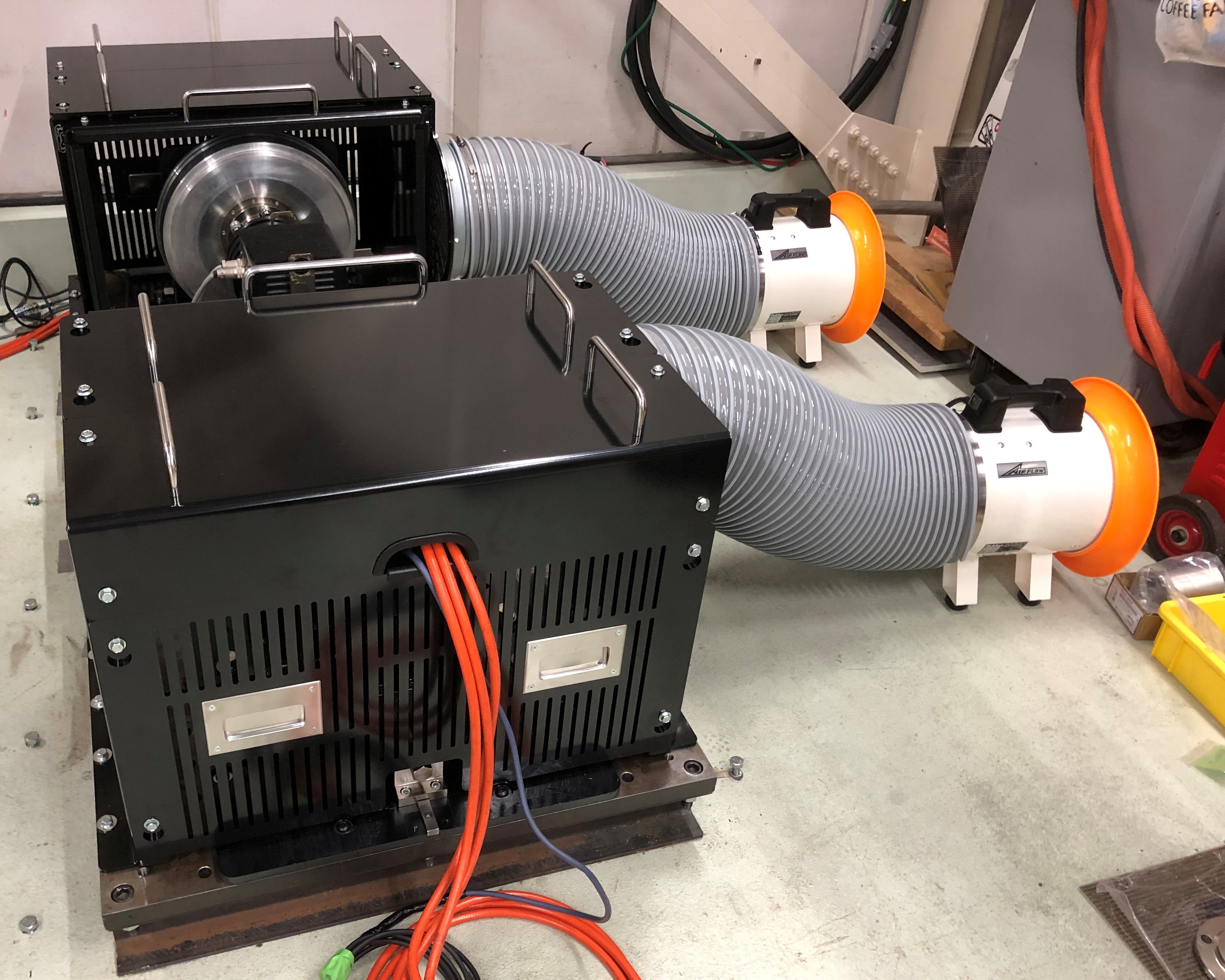

In-wheel motor with built-in inverter(Under development)Motor System Test Bench

We have a test bench for motor system performance testing

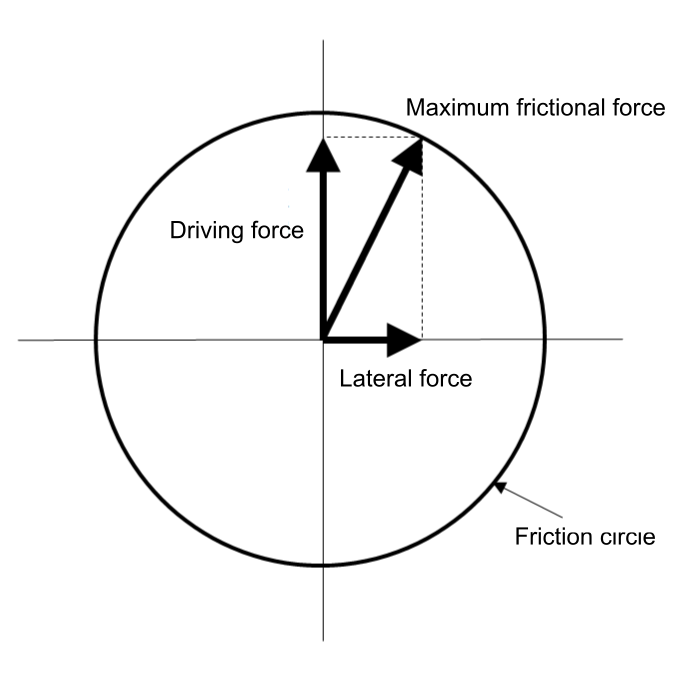

All Wheel Independent Control

The in-wheel motor controls the torque of each wheel independently, and controls the maximum frictional force between each wheel and the road surface on any road surface.

This greatly improves driving safety, stability and comfort.

R&D results

In-wheel motor cooling system(in progress)

| Theme | Development of high-performance immersion cooling technology for in-wheel motors for electric vehicles | |

|---|---|---|

| Project name | Japan-China collaboration project by JICA and the Ministry of Science and Technology of the People's Republic of China | |

| Partner | Tianjin University |

Laminated integrated Magnet

| Theme | Development of high-efficiency, low-priced Nd-Fe-B laminated magnets integrated manufacturing method for EV and FCV drive motors | |

|---|---|---|

| Project name | Ministry of the Environment - Pamphlets for Low Carbon Technology Research and Development Program | |

| Partner | NDFEB |

Development of the latest pressless method for NdFeB magnets

| Theme | Development of the latest pressless method (BNPLP method) for NdFeB magnets for high-efficiency, low-cost motors | |

|---|---|---|

| Project name | NEDO - Technology research and development business for discovering and commercializing seeds of new energy, etc. | |

| Partner | NDFEB |

In-wheel motor with built-in inverter

| Theme | Development of in-wheel motor with built-in GaN transistor inverter |  |

|---|---|---|

| Project name | NEDO - New energy venture technology innovation support business by venture companies, etc. | |

| Partner | Nagoya University, Nagaoka Power Electronics Co,.Ltd. |

New structure Li-ion battery

| Theme | Development of practical technology for new structure Li-ion batteries for electric vehicles |  |

|---|---|---|

| Project name | NEDO - New energy venture technology innovation support business by venture companies, etc. | |

| Partner | - |